Jet problems

Some of the jets pop out

This applies only to snap-in jet inserts. Beginning with 2013, new

spas use jet inserts that screw in and are unlikely to pop out

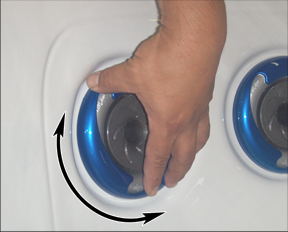

Some jet inserts are designed to rotate about a half a turn in

order to turn on or off water flow. They are also designed to come

out if you turn them past the attachment. When a jet insert is

turned past its attachment point, it can be easily blown out of

the jet body with water pressure. To prevent this, rotate the jet

insert only as far as it will easily turn until it hits the

stopping point.

A jet that keeps popping out may not be pushed in all the way. By

pushing in on the jet insert, you should hear a click. This

indicates that the insert is installed all the way into position.

If there is no click, the jet is in the wrong way and will pop

out.

Sometimes jet inserts weaken over time due to constant exposure to

water and chemicals. If the jets are subjected to extreme

chemicalconditions or abuse, they will weaken and fail.

If the jet insert is a replacement, if it is the wrong size or

type for the jet body, it will not stay in place. Change the

insert to the correct size or type. Many inserts look alike and

have the same size face. The nozzle in the back is where the clips

are located and is what has to match the jet body.

Some of the jets will not rotate

This applies only to jets that are designed to rotate to allow

water pressure to be turned on or off. Some jets are fixed in

place and are always on.

If you are in need of relpacements parts visits

Jets that are designed to rotate should do so easily. Tightness in

jet rotation can be caused by age, chemical or calcium build-up,

or improper insertion. If a rotatable jet does not turn, it may be

stuck. Grip it firmly and rotate it counter-clockwise until it

snaps and pops out of the jet body. Remove it and clean it

thoroughly, then replace it in the jet body. It should rotate more

easily after cleaning.

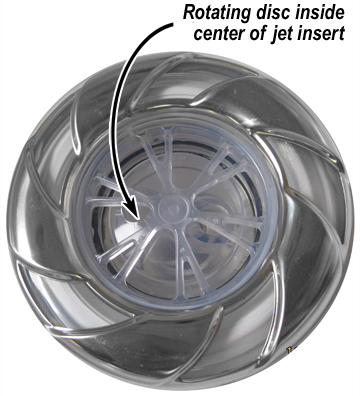

The jet insert will not spin

This refers to jets with a spinner in the center that work with

water pressure and not to jet rotation, which refers to turning on

or off water pressure.

Is the jet insert completely open?

Some jets are able to rotate in order to open or close them.

Rotate the rim of the jet insert o turn the jet on.

Is there water pressure to the jet?

Listen for the sound of the motor. If the pump isn't running, try

pushing the JETS button on the control panel. If the pump that

supplies water to the jets is on low speed, there won't be enough

water to operate the jets. Press the JETS button to activate the

pump on high speed.

Check the water diverter valve. It may be diverting water away

from the group of jets you want to use. Diverter valves direct

water towards the jets to allow water flow to reach them.

Experiment by turning the handle on the valves to see where the

water goes.

Does the jet contain a spinning type jet insert?

Jet inserts come in many different shapes, sizes, and styles.

Spinner jets usually have an internal component that spins or

causes the water to spin. If the jet insert doesn't have that

component, the jet will produce water flow but not the spinning

action that is usually associated with spinner jets. Change the

jet insert to a spinner type of insert (if applicable) to achieve

spinning action.

Is there intermittent spinning action?

If the spinner insert hangs up or spins slowly, it is probably due

to debris in the spinner insert.

Remove the jet insert and clean the debris out of the spinning

mechanism. Use a spray hose to spray out grit from inside the

insert. If it still turns intermittently, the insert will have to

be replaced.

Long hair or lint can also wind up around the shaft of the

spinning insert and cause a slowdown in spinning action. Turn the

insert shaft counter-clockwise to unwind hair and long debris.

Replace insert if necessary.

Some jets are not as powerful as they used to be

This may indicate a problem with water pressure.

Check water pressure troubleshooting on that page.